DOSED stands for Direct-Printed On-Skin Electronic Drug-Delivery, a pioneering technology I contributed to developing.

Microheater Masks

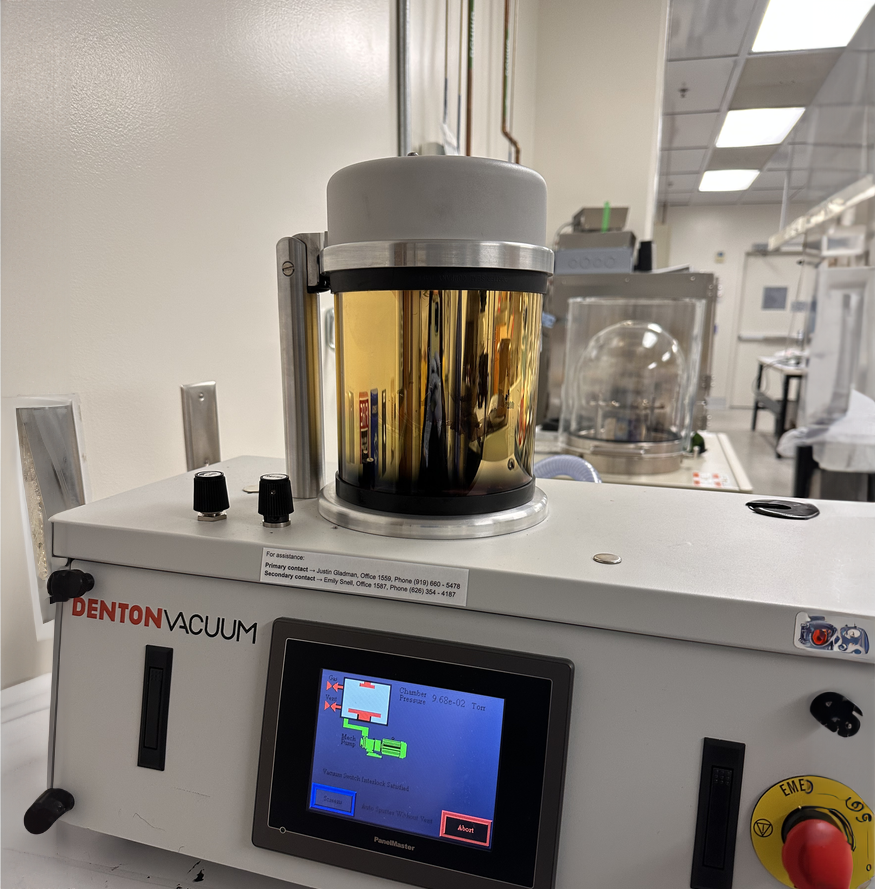

To validate the microheater concept for the drug delivery system, electrodes were printed on Kapton films and glass sheets coated with gold via sputtering. To expedite manufacturing, I developed masks compatible with the Gold Sputter (SPUT3) equipment as seen to the right.

DOSED-Independent Study

DESIGN GOALS

01 EFFICIANCY

Developing product to make manufacturing faster and more effective.

02 CONSISTENT

Precision for each product important to ensure the experiments are accurate.

03 EASE OF USE

Needed a simple solution that people testing could easily and effectively use.

Kapton Film Heaters

The Kapton film masks and trays were 3D modeled and printed using PLA.

The tray is precisely toleranced to fit seamlessly into the Gold Sputter, ensuring rapid testing by allowing it to be placed directly into the system without adjustments.

The masks are precisely toleranced to a specific thickness to prevent gold from coming into contact with this section of the film.

Kapton film tray design

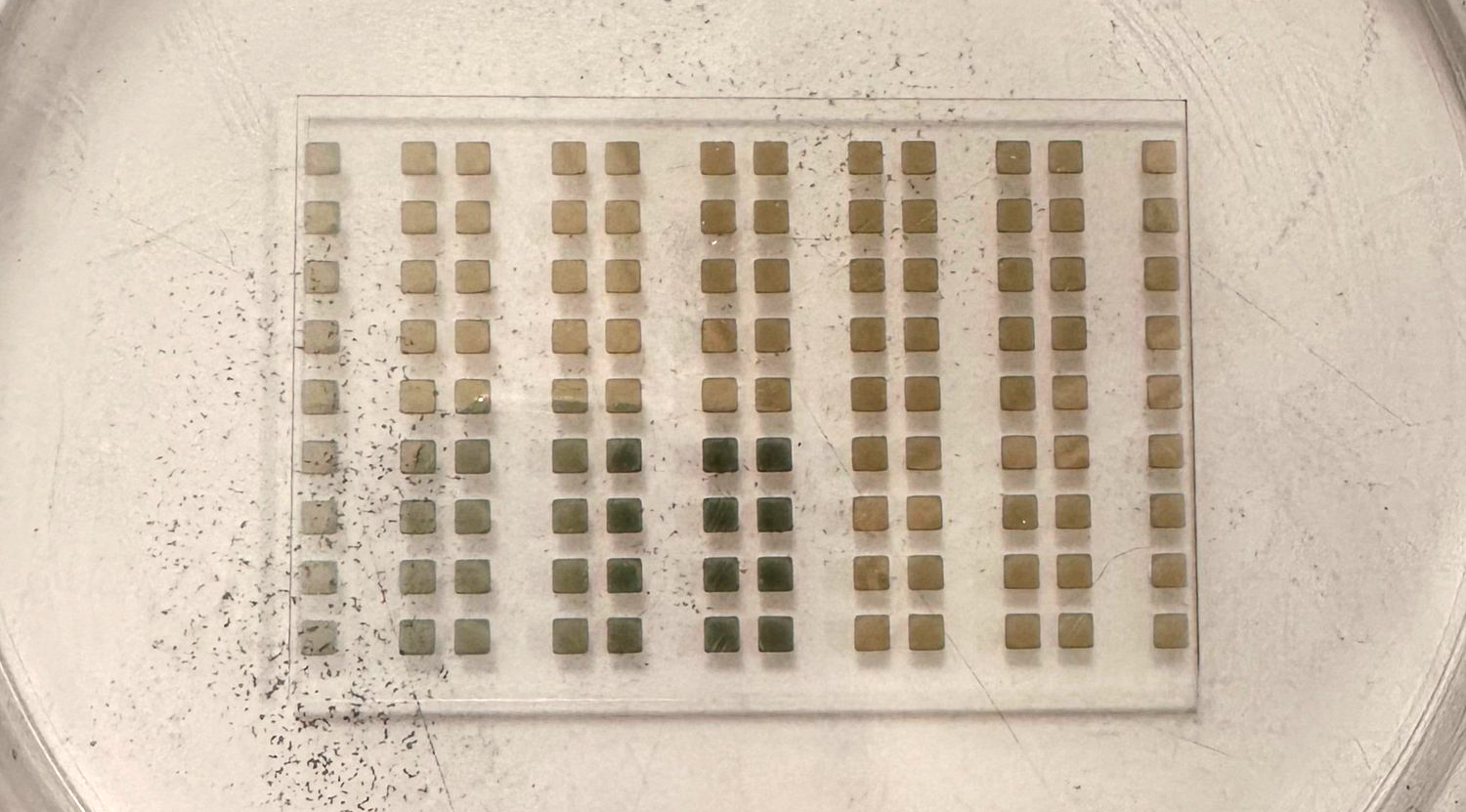

Kapton films in tray with masks

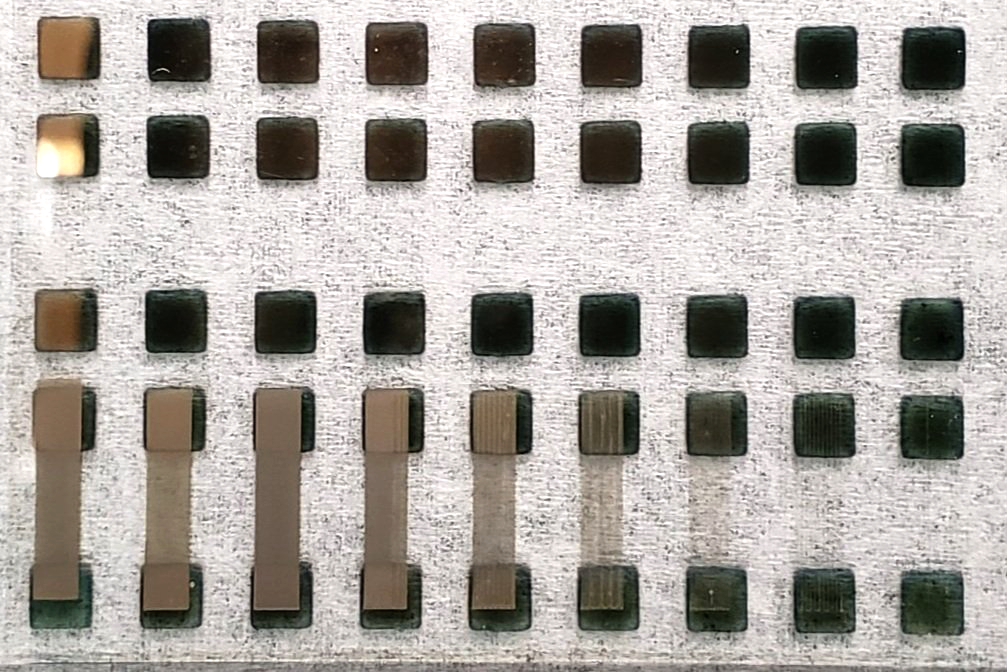

Glass Heaters

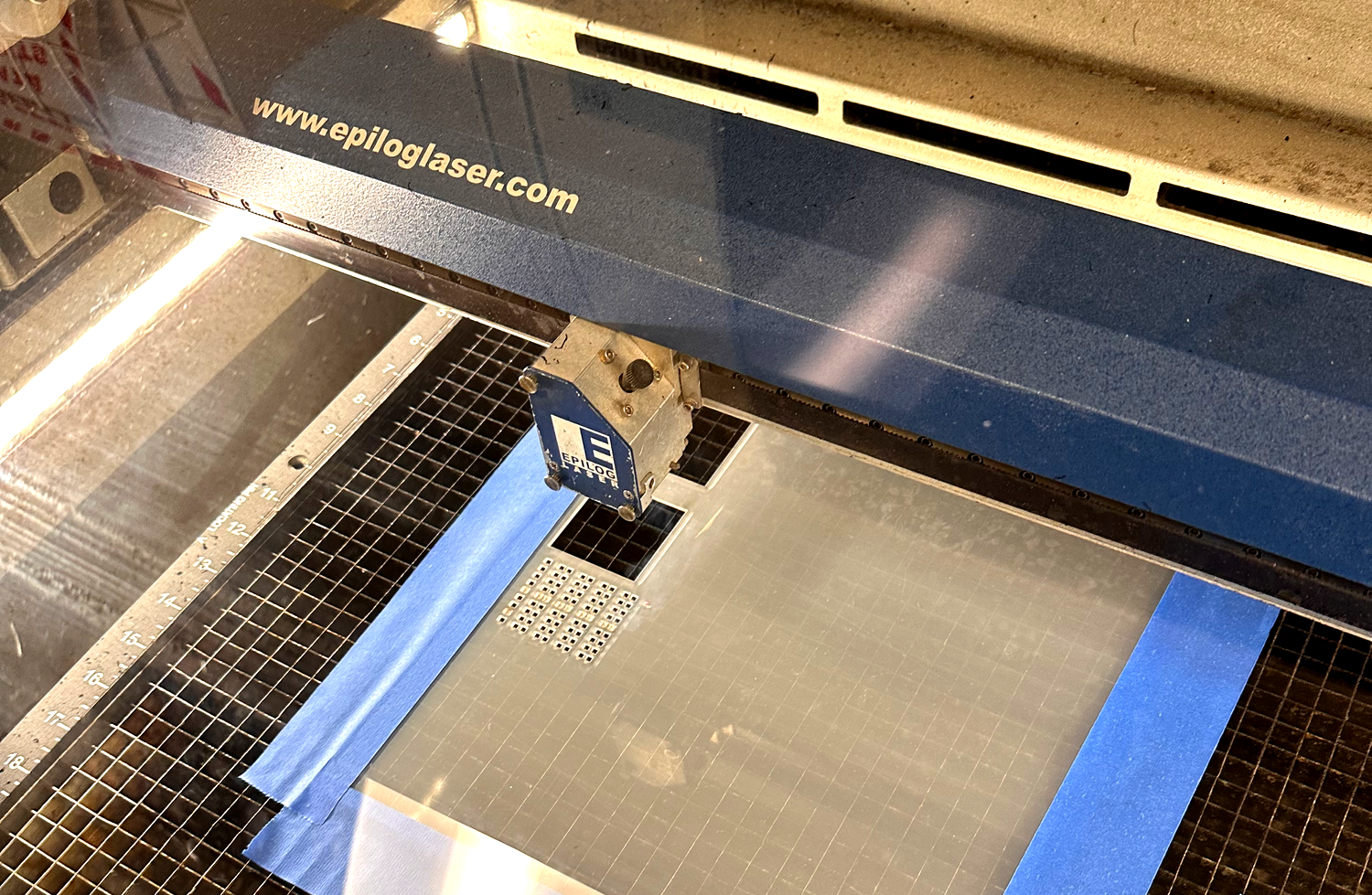

The glass sheet masks are laser-cut from acrylic to ensure precise spacing between each gold pad.

Glass heater masks in laser cutter

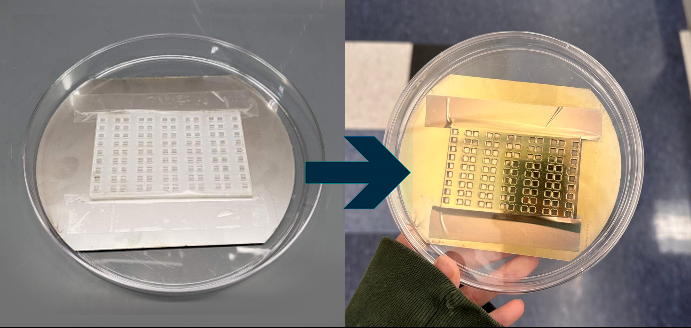

After gold sputter with mask

Before gold sputter

Completed glass heater after mask taken off

Testing

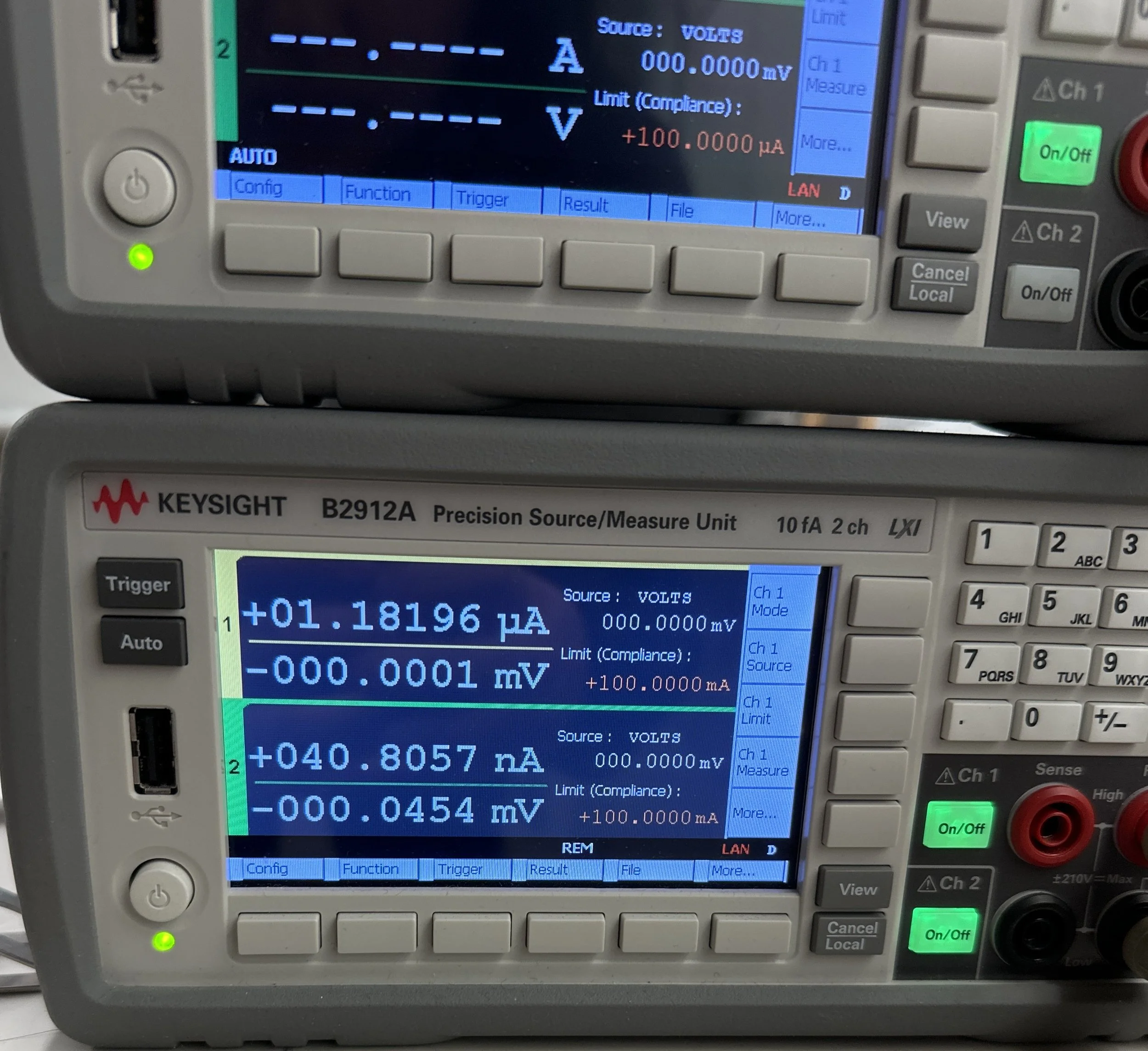

I collected voltage and current data to verify that the microheaters sustained consistent current flow over an extended period, using varying numbers of printed electrodes to demonstrate the effectiveness of the microheater concept.

Multimeter values displaying voltage and current

Range of electrodes printed on glass

PROJECT FEATURES

Testing

Manufacturing

3D Printing